The 14 sizes of common roller chains can be found ranging from 25 to 240 together with individuals in conformity with ANSI (American Nationwide Common Institute), and ISO (Global Organization for Standardization).

The chains not just meet the demands for your minimum tensile strength prescribed by ANSI and ISO, however they also supply the major class good quality from the planet which include a high fatigue strength

Appropriate employs

?Standard use for driving and lifting equipment.

Examples

?Driving transfer units along with other equipment. For multilevel SHARP Top rated CHAINS parking.

Collection of chains

For variety of a chain, see the tables of “Max. Horsepower Ratings” for common roller chains and “Designing of Chain Transmission”. On the other hand, only for a unique case of lower pace and much less shock, “Low-speed selection” strategy also can be referred to.

Normal roller chains up to five strands can be found. The normal technique for connecting pins and plates is rivet sort (RP).

The cotter variety (CP) is accessible for normal chains and HK chains of 80 or more substantial.

Sprockets

The normal roller chains can be engaged with typical sprockets with the corresponding nominal numbers. For sprockets, refer for the table of “Dimensions” for every dimension of chain.

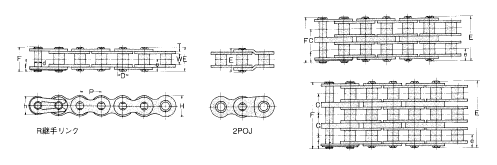

Connecting hyperlinks and offset back links

For connecting back links and offset backlinks, refer on the table of “Dimensions” for each size of chain.

The connecting backlinks are generally R or C connecting hyperlinks during which the pins are clearance-fitted with the connecting plate. Considering that clearance-fitted hyperlinks are inferior towards the base chain in Max. allowable stress as while in the situation of one-pitch offset hyperlinks (OJ), “Low-speed selection” can’t be referred to. Because the Max. kilowatt ratings are decided taking  into consideration the strength of connecting links and OJ, the clearance-fitted connecting links and OJ could be employed if your chains are selected according towards the “General selection”. Whenever a greater Max. allowable stress is required to the connecting link, make use of the interference-fitted connecting link (H connecting link) of the HI-PWR-S chain, and during the situation of offset back links, use 2POJ.

into consideration the strength of connecting links and OJ, the clearance-fitted connecting links and OJ could be employed if your chains are selected according towards the “General selection”. Whenever a greater Max. allowable stress is required to the connecting link, make use of the interference-fitted connecting link (H connecting link) of the HI-PWR-S chain, and during the situation of offset back links, use 2POJ.