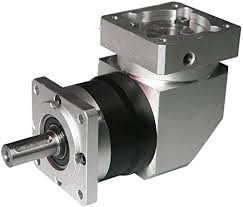

WORM SERVO GEAR REDUCER

Features

Wide variety of servo gearboxes, designed to fit almost all servo motors found on the market

Designed for the best torsional stiffness and the cheapest angular backlash, intended for the maximum torque and overhung loads

Bush with slot machines and hub clamp for servomotor coupling

Benefits

Enhanced dimensional compactness due to direct servomotor coupling

Widest range of possible servomotors coupling dimensions.

The right technical solution because of a comprehensive selection of sizes, gear stages, transmission ratios, designs and non-standard designs.

Catalogs:

Servo gear reducers (worm, coaxial, helical and bevel helical devices) Catalog SR

Operating instructions:

Operating instructions for equipment reducers and gearmotors (UTD.045)

EP Drive Systems, Inc. is very happy to announce the expansion of our selection of Servo Reducers, right now offering five degrees of precision to meet any software requirements. The five degrees of precision offered allows a machine developer to select the required reducer precision to meet their needs and their budget. They are available in both in-line and right-angle variations, in torques up to 7,376 lb.ft. and ratios to 3,392:1.

Typical applications for these reducers include rotary & linear axis drives, and materials handling axis drives. Industries served include Material Managing, Automation, Aerospace, Machine Tool and Robotics.

The mounting faces of the HT, HP, E and B versions are identical, making it possible to interchange a unit with a higher or lower accuracy unit if needed.

A wide range of engine couplings and mounting flanges are for sale to the complete reducer range to attach virtually any servo motor and the hollow bore output can be utilized to attach output shafts, pinion shafts, or other drive elements.

These reducers are typically selected predicated on the peak cycle forces, which usually happen during accelerations and decelerations. These cycle forces depend on the powered load, the rate vs. period profile for the cycle, and any other external forces functioning on the axis. For more selection information, please follow this PDF hyperlink.

For application & selection assistance, please call, fax or email us. Your application info will be reviewed by our engineers, who will recommend the best solution for the application.

EP Inc. offers a full selection of modular servo gearboxes /worm reducers. The modular design permits configurations with motor insight flange and result pinion for rack and pinion drives, as well as solid output shafts, Hollow bore output, and insight shafts for all the positioning applications. The modular design allows for universal mounting of the gearbox in any orientation.

They can be utilized on motors with a NEMA23 standard flange via an adaptor kit. As the gears are normally angled, they result in a short total amount of the electric motor and its gear.

The series can also be delivered both right- and left-angled and with output shafts on both sides. A 30-mm machine recess for centering and a 4 M5 threaded mounting hole may also be constructed on the gear’s output side.

Built with a straightforward and robust style, the series offers gearing ratios that range from 6:1 to 75:1. The user may also customize the materials through the order, so as to match the gear to its intended program.

The Precision Planetary Gears of the EPRG series contains a thorough range of low backlash planetary gearboxes, with up to class 3′ precision, obtainable in several gear frame sizes, with single or multiple stage reduction (for gear ratios from 1:3 to 1 1:1,000). These models also include versions with dual shaft, right angle shaft and right angle output, in addition to a full range of adapters for engine mounting, making them with the capacity of meeting certain requirements of actually the most varied applications. They are created for use with built-in servo and stepper EP motors, mounted directly or via adaptor flanges, but can also be used in combination with other EP motor types. This selection of products is based on years of experience and represents the outcome of a decade-long study targeted at improving performance.

Maximum precision and dynamics, coupled with extraordinary torque density, are the key requirements specific for reliable servo gearboxes in practice. EP provides servo gearboxes for just about any application and any overall performance range. Our low-backlash planetary and right-position gearboxes reflect our passion for creativity and the highest levels of precision.

Worm equipment reducers provide market enhance solution with efficiency and flexibility. Low number of basic models could be applied to a wide range of power ratings guaranteeing top performance and reduction ratios from 5 to 1000.

Gear reducers and servo gearboxes of EP Precision Machinery Co., Ltd. are designed for high-performance mechanical devices. When the motor quickness must be reduced, the result torque improves and send torque completely to the application form. We believe that clients will appreciate our gear reducer to accomplish their demand. Just check out EP, you can obtain more information regarding servo gearheads, servo gearboxes, and equipment reducers. We continue to keep going forward for your support.

Plug the Acceleration Reducer into the desired channel of your receiver, and plug the business lead from your own servo (or servo wye) into the man servo lead from the circuit board. The set screw on the blue trim pot, located close to the top of the primary circuit board, is utilized to control the rate of the servo. Convert the set screw fully clockwise (CW) for normal servo speed without speed reduction, fully counter-clockwise (CCW) for optimum speed reduction, or anywhere in between for partial swiftness reduction. The red LED indicates three feasible conditions: Gradual Blinking = No Transmission; Solid On = No Speed Decrease; Fast Blinking = Reduced Velocity Setting

Please note that if you make any change to the speed setting while the receiver is on, you must cycle capacity to the receiver (turn if off and back on) for the new speed environment to take impact. This circuit may also be used in conjunction with our Servo Reverser to trigger flap or retract servos to turn in reverse directions for right function. Instructions are included for easy installation and use.

IMPORTANT NOTE: This product will only focus on a normal, proportional servo. It will NOT focus on a retract-type servo, because they do not acknowledge any servo positions other than clockwise (CW) and counter-clockwise (CCW). Retract servos can’t be slowed down, also by a transmitter that includes this function, as their style and electronics don’t allow it. Verify the FAQ page for more information.

This device will certainly reduce the speed of any regular, proportional servo. Connect it between your receiver and the servo (or servos) you wish to control for a more scale-like motion of flaps or retracts. Adjustable, it can be set to reduce the quickness of your servo from super-slow motion to no speed reduction at all, with an almost infinite number of positions among. Maximum reduction period for a servo to travel 90 degrees is about 14 seconds, minimum period (no reduction) is simply the normal acceleration of the servo. Great for reducing or getting rid of the tendency of a plane to “balloon up” when flaps are deployed. It can be used to control more than one servo by usage of a normal servo Y.

This is the new regulated version that can be used  on radio systems powered by any size or kind of battery, including 4.8-6.0 volt 4-5 cell Ni-Cad/Ni-MH batteries, and HV (high voltage) receivers that operate on 2-cell 6.6-8.4 volt Li-Po/Li-Ion/Existence batteries. This unit won’t reduce the voltage likely to your servos.

on radio systems powered by any size or kind of battery, including 4.8-6.0 volt 4-5 cell Ni-Cad/Ni-MH batteries, and HV (high voltage) receivers that operate on 2-cell 6.6-8.4 volt Li-Po/Li-Ion/Existence batteries. This unit won’t reduce the voltage likely to your servos.

The EP Gear Reducer is the perfect solution for servomotor applications such as packaging devices, gantries, injection molding devices, pick and place, and linear slides.Provided in concentric shaft, right position solid shaft, and right angle hollow shaft styles with modular adaptor flanges and keyless compressible bushings to easily mount to any manufacturer’s servo electric motor. The EP Series helical gears have got slanted teeth in comparison to spur gears with straight cut teeth, generating a smoother gear mesh, yielding significantly lower noise levels.

The low backlash EP planetary servo gear units are designed for the 30 to 350 Nm (265 to 3100 lb-in) torque classes. These were designed to combine the greatest possible versatility and cost-efficiency because not every application requires high-performance elements.

They provide a basis for diverse, dynamic and cost-optimized drive solutions.

The EP planetary servo gear units are available in the following versions:

PSC = B5 output, smooth output shaft

PSKC = B5 result, with keyway

PSCZ = B14, output, smooth output shaft

PSKCZ = B14 result, with keyway

Find out more about servo gear reducer below.